The Client

The ClientThe client is one of the leading integrated temperature-controlled logistics service providers, specialized in providing warehousing, distribution, and other value-add services across the country.

They owe currently 33 State of Art warehouses present across the country, 1 Lac+ Pallet capacity, 293 Fleet of refrigerated vehicles and 1500+ workforce. The company serves their customer with palletized storage, multi-facility and environment-friendly refrigerant, 24*7 operations support and end-to-end solution.

The Challenges

The ChallengesThe day-to-day activities of the client typically involved the management of inbound and outbound transportation, planning of synchronized supply and demand, material handling, designing logistics network, warehouse management, and order fulfillment.

The client was using third-party software for maintaining and managing the transportation activities, which was functioning in silos. Sales and purchase orders, online payments, product catalogs were managed by different software. Without integration of the systems, the ERP data was moved manually into the numerous other systems, which made it more error-prone and limited the visibility of operations.

Post-implementation of section 269ST in the Income Tax Act, the application demanded a secure and resilient feature to be implemented in the payables and receivables module of the system, that must comply under the provisions of Section 269ST, ensuring no conditions are being violated.

In addition to that, the client was charging their customers for the used pallets only. The unoccupied pallets resulted in the loss of revenue. They required a solution to overcome this problem so that unoccupied storage pallets could be used as well as transportation costs are saved.

The Objective

The ObjectiveA leading Logistics Services provider desired a robust system to manage the supply chain across 33 state-of-the-art warehouses with over 1500+ workforce, for leading Global CPG brands. They sought seamless and tight multichannel ERP integration resulting in data accuracy across channels, better visibility of operations and reduced manual intervention.

The Solution

The SolutionJK Tech re‐engineered the business processes within and beyond the organizational scope and integrated Dynamics NAV with the third-party software and the sporadic databases into one database that resides in Dynamics NAV. In addition, online payments and receipt entries from third parties were integrated into NAV and synced in one database for a structured financial view.

After integration of Dynamics NAV with third-party software, all components of the business were managed including sales, purchase, warehousing and finances in the NAV database. The user-friendly and flexible system proved impactful across all departments. Since all the relevant data was now present at one place, real-time data entries and decision-making were easier and faster.

Additionally, Real-time data entries also supported pallet management. With the help of real-time data available in the application, the pallets can be tracked, and the user can easily get information like the current status of the pallet, location of the pallet, where it’s been and how often it’s been moved. This information helped the user filling empty pallets on the road for some other customer while delivering to another customer, which uses up unoccupied pallet storage as well as saves transportation costs on visiting the in-transit customer. The manual workload and backlog that was cumbersome were now automated. The client was now having easy access to the information about the goods that are dispatched from the supplier and the procurement and delivery of the goods.

To comply with the provisions of Section 269ST of Income-tax, the feature of payment limit functionality was put into action into the system corresponding to each warehouse location, capping the transactional amount at a time in the finance module thus ensuring the verification of every transaction taking place. This feature supported adherence to each and every condition of the section and securing the client from contravening the provisions and falling into a penalty.

Overall, the upgradations and integrations done by the team revolutionized the client’s daily operations including logistics functions such as customer service, sourcing and procurement, production planning and scheduling, packaging, and assembly. As a result, the client now has the capacity to handle more work, bring on new customers and take its business growth to the next level.

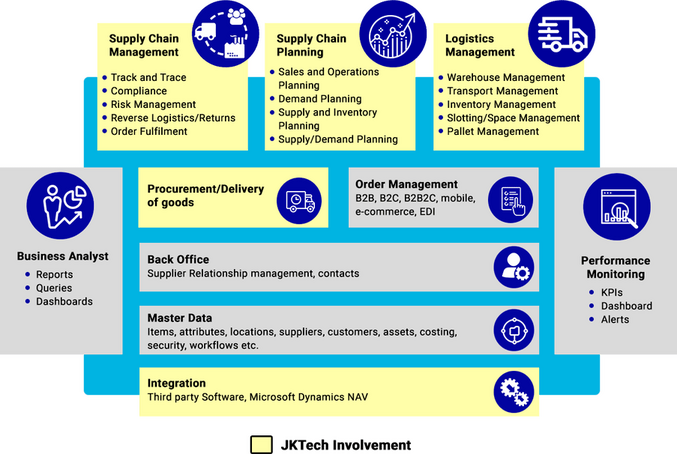

Fig 1: JK Tech Solution Footprint

The Benefits

The Benefits Happy Customer

Happy CustomerLeading Integrated Temperature Controlled Logistics Service ProviderSupply Chain Professional

We believe that JK Tech is not just a vendor but a technology partner.

The overall support provided by the JK Tech team has been very satisfactory. They have proficiently supported us in accomplishing critical projects across the business with complete adherence to the committed deadlines.

Talking about projects in general, they successfully rolled out a transformed billing logic to reinforce our billing scheme, they provided us support on integrations of our Transport Management System with our core ERP Dynamics Navision. They are an amazing team to work with. We are really optimistic about partnering with them for our upcoming projects.

Use the form below to get in touch

Hello, I am Aria!

Would you like to know anything in particular? I am happy to assist you.